- Home

- Fleet Vehicle Maintenance

- Auto Body Repair

Auto Body Repair

Auto body repair products aid in the repair and renovation of vehicle exteriors to remove dents, fill gouges, and restore surfaces to their original condition. Sealants and fillers help repair and reconstruct exterior auto body parts. Tools ease removal, assembly, and reconstruction of auto body com .....Read More

Frequently Asked Questions

What are the best auto body repair products for fixing dents?

How do I choose the right sealant for my car's exterior?

What tools are essential for auto body repair?

How do I use body fillers to repair gouges in my car?

What is the best way to remove and replace auto body parts?

How do I properly mask a vehicle before painting?

What types of tapes are best for reducing squeaking in vehicles?

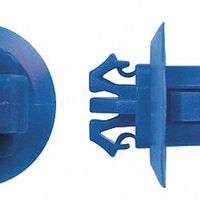

How do I install body clips to keep trim intact?

What equipment is needed to support auto body parts during repair?

How do hinge and bushing kits work for replacing door parts?