Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Fleet Vehicle Maintenance

- Vehicle Accessories

- Exterior Vehicle Accessories

- Truck Bed Tailgate Equipment

Truck Bed & Tailgate Equipment

This equipment makes trucks more useful, organized, and helps them stay cleaner. Bed liners and drain mats protect the cargo areas of the truck from scratches or damage from loads. Bed coatings add a textured finish that guards against chips, scratches, rust, and fading. Tailgate parts frequently br .....Read More

Frequently Asked Questions

What are the benefits of using bed liners in trucks?

Bed liners offer several benefits for trucks, enhancing both functionality and longevity. Firstly, they provide protection against physical damage. By acting as a barrier, bed liners shield the truck bed from scratches, dents, and abrasions caused by hauling heavy or sharp objects. This protection helps maintain the truck's resale value by preserving its appearance.

Secondly, bed liners offer corrosion resistance. They prevent moisture from seeping into the truck bed, which can lead to rust and corrosion over time. This is particularly beneficial in regions with high humidity or frequent rain.

Thirdly, bed liners improve cargo stability. Many liners have textured surfaces that reduce slippage, ensuring that cargo remains in place during transit. This minimizes the risk of damage to both the truck and the cargo.

Additionally, bed liners can enhance the truck's aesthetic appeal. Available in various materials and finishes, they allow owners to customize the look of their truck bed, adding a sleek and polished appearance.

Furthermore, bed liners can provide sound dampening. They reduce noise and vibrations caused by cargo movement, leading to a quieter ride.

Lastly, bed liners are easy to maintain. Most can be cleaned with simple soap and water, making upkeep straightforward and hassle-free.

Overall, bed liners are a practical investment for truck owners, offering protection, durability, and aesthetic enhancement.

How do drain mats protect the cargo area of a truck?

Drain mats protect the cargo area of a truck by providing a barrier between the cargo and the truck bed, preventing damage and maintaining cleanliness. They are designed with grooves or channels that facilitate the drainage of liquids, preventing water, oil, or other substances from pooling. This drainage capability helps to avoid rust and corrosion on the truck bed, which can occur when moisture is trapped against the metal surface.

Additionally, drain mats offer a non-slip surface, reducing the risk of cargo shifting during transit. This stability is crucial for preventing damage to both the cargo and the truck. The mats also cushion the cargo, absorbing shocks and vibrations from the road, which further protects delicate items.

Drain mats are typically made from durable materials like rubber or heavy-duty plastic, which are resistant to chemicals, oils, and extreme temperatures. This durability ensures long-term protection and reduces the need for frequent replacements. The mats are also easy to remove and clean, allowing for quick maintenance and ensuring that the truck bed remains in good condition.

By preventing direct contact between the cargo and the truck bed, drain mats help preserve the resale value of the truck by minimizing wear and tear. They also contribute to a safer and more efficient transportation process by ensuring that the cargo remains secure and the truck bed is protected from potential damage.

What is the purpose of bed coatings for trucks?

The purpose of bed coatings for trucks is to provide protection, enhance durability, and improve the functionality of the truck bed. These coatings serve several key functions:

1. **Protection Against Damage**: Bed coatings protect the truck bed from physical damage such as scratches, dents, and abrasions that can occur when loading and unloading cargo. They act as a barrier against impacts and wear and tear.

2. **Corrosion and Rust Prevention**: By sealing the truck bed, coatings prevent moisture, chemicals, and salt from reaching the metal surface, thereby reducing the risk of rust and corrosion. This is particularly important in harsh weather conditions or when transporting corrosive materials.

3. **Enhanced Durability**: Coatings increase the lifespan of the truck bed by providing a tough, resilient surface that can withstand heavy use. This durability is crucial for trucks used in demanding environments, such as construction or agriculture.

4. **Improved Traction**: Many bed coatings have a textured surface that provides better grip, reducing the likelihood of cargo shifting during transport. This helps in maintaining the safety and security of the load.

5. **Aesthetic Appeal**: Coatings can enhance the appearance of the truck bed, giving it a clean, finished look. They are available in various colors and finishes, allowing for customization to match the truck's overall design.

6. **Ease of Maintenance**: A coated truck bed is easier to clean and maintain. The smooth surface prevents dirt and debris from sticking, making it simpler to wash and keep in good condition.

7. **Noise Reduction**: Coatings can dampen noise and vibrations caused by cargo movement, leading to a quieter ride.

Overall, bed coatings are a practical investment for truck owners looking to protect their vehicle, extend its lifespan, and maintain its value.

How can I prevent my truck's tailgate parts from breaking?

1. **Regular Maintenance**: Inspect the tailgate and its components regularly for signs of wear and tear. Tighten any loose bolts and replace worn-out parts promptly.

2. **Proper Use**: Avoid slamming the tailgate shut. Close it gently to prevent stress on the hinges and latches.

3. **Weight Management**: Do not exceed the tailgate's weight limit. Distribute cargo evenly and avoid placing heavy items directly on the tailgate.

4. **Lubrication**: Apply lubricant to the hinges, latches, and cables to ensure smooth operation and reduce friction that can lead to wear.

5. **Protective Coatings**: Use rust-resistant coatings or sprays on metal parts to prevent corrosion, especially if you live in a humid or coastal area.

6. **Weather Protection**: Use a tailgate cover or tarp to protect against harsh weather conditions. This can prevent rust and damage from rain, snow, and UV rays.

7. **Aftermarket Accessories**: Consider installing tailgate dampers or assist systems to control the speed of opening and closing, reducing impact stress.

8. **Avoid Overloading**: Do not use the tailgate as a step or seat unless it is designed for such use. Overloading can strain the hinges and cables.

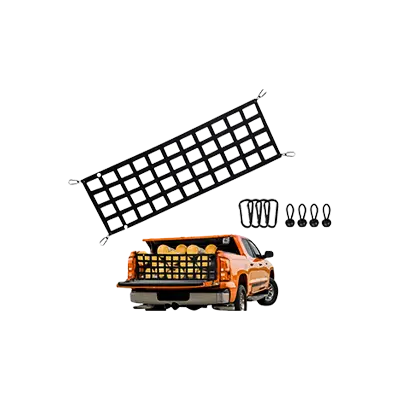

9. **Secure Cargo**: Use tie-downs to secure cargo and prevent it from shifting and damaging the tailgate during transit.

10. **Professional Inspection**: Have a professional inspect the tailgate mechanism during routine vehicle maintenance to catch potential issues early.

11. **Quality Parts**: Use high-quality replacement parts if repairs are needed. OEM parts are often more reliable than cheaper alternatives.

12. **Education**: Educate anyone who uses your truck on the proper handling of the tailgate to ensure consistent care.

What are the signs that my truck's tailgate needs repair?

1. **Difficulty Opening/Closing**: If the tailgate is hard to open or close, it may indicate misalignment or damaged hinges.

2. **Unusual Noises**: Squeaking, grinding, or popping sounds when operating the tailgate can signal issues with the hinges or latch mechanism.

3. **Visible Damage**: Dents, rust, or cracks on the tailgate surface or frame can compromise its structural integrity.

4. **Latch Problems**: If the tailgate doesn’t latch securely or pops open unexpectedly, the latch mechanism may be faulty or misaligned.

5. **Sagging**: A tailgate that sags or doesn’t align properly with the truck bed may have worn-out hinges or support cables.

6. **Loose or Missing Parts**: Missing bolts, screws, or other components can affect the tailgate’s functionality and safety.

7. **Corrosion**: Rust on the tailgate or its components can weaken the structure and lead to further damage.

8. **Electrical Issues**: For tailgates with integrated electronics (e.g., cameras, sensors), malfunctioning components can indicate wiring or connection problems.

9. **Water Leaks**: If water seeps into the truck bed through the tailgate, it may not be sealing properly.

10. **Cable or Strap Wear**: Frayed or broken support cables or straps can lead to a sudden drop or failure of the tailgate.

11. **Alignment Issues**: If the tailgate doesn’t sit flush with the truck bed, it may need realignment or hinge adjustment.

12. **Paint Damage**: Chipped or peeling paint can expose the metal to rust and corrosion.

13. **Vibration or Rattling**: Excessive movement or noise while driving can indicate loose components or alignment issues.

How do latch, hinge, and handle repair kits work for tailgates?

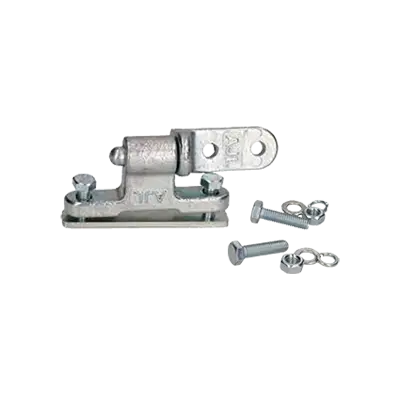

Latch, hinge, and handle repair kits for tailgates are designed to restore the functionality of these components, which are crucial for the secure and smooth operation of a vehicle's tailgate.

Latch repair kits typically include replacement latches, springs, and sometimes rods or cables. These components work together to secure the tailgate in a closed position. Over time, latches can wear out or become misaligned, leading to difficulty in opening or closing the tailgate. The repair kit allows for the replacement of worn parts, ensuring the latch mechanism operates smoothly and securely.

Hinge repair kits usually contain new hinges, bushings, and pins. Tailgate hinges can become corroded or damaged due to constant use and exposure to the elements. This can result in misalignment or difficulty in opening and closing the tailgate. By replacing the worn hinges and associated components, the repair kit restores proper alignment and movement, ensuring the tailgate opens and closes with ease.

Handle repair kits often include a new handle, clips, and sometimes linkage components. The handle is the primary interface for opening the tailgate, and it can break or become loose over time. A repair kit allows for the replacement of the handle and any associated parts, ensuring that the tailgate can be easily opened from the outside.

Overall, these repair kits provide a cost-effective solution for maintaining the functionality and safety of a vehicle's tailgate. They typically come with instructions for installation, allowing vehicle owners to perform the repairs themselves or with minimal professional assistance.

What is the best way to maintain a truck's cargo area?

To maintain a truck's cargo area effectively, follow these steps:

1. **Regular Cleaning**: Clean the cargo area frequently to prevent dirt, debris, and moisture buildup. Use a pressure washer for thorough cleaning, and ensure the area is completely dry to prevent rust and mold.

2. **Protective Coating**: Apply a protective liner or coating, such as a spray-on bed liner, to shield the cargo area from scratches, dents, and corrosion. This also helps in maintaining the truck's resale value.

3. **Inspect for Damage**: Regularly inspect the cargo area for signs of wear, rust, or damage. Address any issues immediately to prevent them from worsening.

4. **Rust Prevention**: Use rust inhibitors or anti-rust sprays, especially in areas prone to moisture. Ensure proper drainage to avoid water accumulation.

5. **Secure Cargo**: Use tie-downs, straps, or nets to secure cargo and prevent it from shifting during transit, which can cause damage to both the cargo and the truck.

6. **Load Evenly**: Distribute weight evenly across the cargo area to avoid undue stress on the truck's suspension and to maintain balance.

7. **Weather Protection**: Use tarps or tonneau covers to protect the cargo area from weather elements like rain, snow, and UV rays, which can cause damage over time.

8. **Avoid Overloading**: Adhere to the truck's load capacity to prevent damage to the cargo area and the vehicle's overall performance.

9. **Regular Maintenance**: Schedule regular maintenance checks with a professional to ensure all components of the cargo area, such as hinges and locks, are functioning properly.

10. **Use Floor Mats**: Consider using removable floor mats to protect the base of the cargo area from spills and stains.

By following these steps, you can ensure the longevity and functionality of your truck's cargo area.