Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Pumps

- Well Pumps Systems

- Submersible Deep Well Pumps Motors Heads

Submersible Deep-Well Pumps, Motors & Heads

Submersible deep-well pumps push water up the well to the surface making them effective for wells that are up to several hundred feet deep. Submersible deep-well pump heads allow for the use of an existing pump motor with a compatible pump body and impeller without replacing the entire pump. Control .....Read More

Frequently Asked Questions

What is a submersible deep-well pump?

A submersible deep-well pump is a type of pump designed to operate while fully submerged in water, typically used for extracting water from deep wells. These pumps are cylindrical and slender, allowing them to fit into narrow well casings. They are commonly used in residential, agricultural, and industrial applications where water needs to be lifted from significant depths.

The pump consists of a hermetically sealed motor coupled to the pump body, which prevents water from entering and damaging the motor. This design allows the pump to operate underwater, reducing the risk of cavitation and increasing efficiency. The motor is usually an electric motor, and the entire assembly is lowered into the well, with the pump intake positioned below the water level.

Submersible deep-well pumps are capable of lifting water from depths of several hundred feet, making them ideal for deep wells where surface pumps would be ineffective. They are available in various sizes and capacities, allowing for customization based on the specific requirements of the well and the volume of water needed.

These pumps are known for their reliability and durability, as they are designed to withstand harsh underwater conditions. They require minimal maintenance, as they are less prone to mechanical issues caused by air exposure. However, installation and removal can be more complex compared to surface pumps, often requiring specialized equipment.

Overall, submersible deep-well pumps are an efficient and effective solution for accessing groundwater from deep sources, providing a consistent and reliable water supply for various needs.

How does a submersible deep-well pump work?

A submersible deep-well pump operates by being fully submerged in the fluid it is designed to pump, typically water from a well. The pump consists of a hermetically sealed motor close-coupled to the pump body. This design prevents water from entering the motor and causing damage.

The pump is lowered into the well, and when activated, the motor drives an impeller or a series of impellers. These impellers are responsible for creating a centrifugal force that pushes the water upward through the pump. As the impeller spins, it increases the velocity of the water, converting kinetic energy into pressure energy. This pressure forces the water to move through the pump and up the discharge pipe to the surface.

The pump's motor is powered by electricity, which is supplied through a waterproof cable. The motor is typically an electric induction motor, which is efficient and reliable for continuous operation. The entire assembly is designed to be narrow enough to fit inside the well casing, which can be as small as 4 inches in diameter.

Submersible pumps are advantageous because they are less prone to cavitation, a problem that can occur with surface pumps when the pressure in the pump inlet drops below the vapor pressure of the liquid. Being submerged, the pump is always primed and ready to operate, eliminating the need for priming and reducing the risk of air lock.

Overall, submersible deep-well pumps are efficient, reliable, and capable of lifting water from significant depths, making them ideal for residential, agricultural, and industrial applications.

What are the advantages of using a submersible deep-well pump?

Submersible deep-well pumps offer several advantages:

1. **Efficiency**: These pumps are highly efficient as they push water to the surface rather than pulling it, reducing energy consumption and improving performance.

2. **Prevention of Cavitation**: Being submerged, they are less prone to cavitation, a common issue in surface pumps where vapor bubbles form and collapse, potentially causing damage.

3. **Space-Saving**: Installed within the well, they save space on the surface, making them ideal for areas with limited space.

4. **Quiet Operation**: Submersible pumps operate quietly since they are underwater, reducing noise pollution.

5. **Protection from Elements**: Being underwater, they are protected from weather conditions and external damage, enhancing durability and longevity.

6. **Self-Priming**: These pumps are self-priming, eliminating the need for manual priming and reducing maintenance efforts.

7. **High Pressure**: Capable of delivering high water pressure, they are suitable for deep wells and applications requiring significant lift.

8. **Versatility**: They can handle a variety of water types, including those with sand or other particulates, due to their robust design.

9. **Reduced Risk of Overheating**: The surrounding water cools the motor, reducing the risk of overheating and extending the pump's lifespan.

10. **Cost-Effective**: Although the initial investment may be higher, their efficiency and low maintenance requirements can lead to cost savings over time.

11. **Reliability**: Designed for continuous operation, they offer reliable performance, crucial for applications like irrigation and water supply.

These advantages make submersible deep-well pumps a preferred choice for many residential, agricultural, and industrial applications.

How deep can a submersible deep-well pump operate?

A submersible deep-well pump can typically operate at depths ranging from 25 feet to over 400 feet, depending on the model and design. These pumps are engineered to function underwater, making them ideal for deep wells where surface pumps are ineffective. The depth capability of a submersible pump is determined by several factors, including the pump's horsepower, the diameter of the well, and the specific application requirements.

The pump's horsepower is crucial as it dictates the amount of energy available to lift water from deep underground to the surface. Higher horsepower pumps can operate at greater depths, often exceeding 400 feet. The well's diameter also plays a role, as it must accommodate the pump's size while allowing for efficient water flow.

Submersible pumps are designed to handle high pressure and are constructed from durable materials like stainless steel to withstand the harsh conditions found at significant depths. They are equipped with multiple impellers that increase the pressure and enable the pump to move water vertically over long distances.

In addition to the mechanical aspects, the electrical components of the pump, such as the motor and wiring, must be capable of operating efficiently at these depths. Proper installation and maintenance are essential to ensure the pump's longevity and performance.

Overall, while standard submersible deep-well pumps can operate effectively at depths up to 400 feet, specialized models can reach even greater depths, depending on the specific needs of the application and the technological advancements in pump design.

What maintenance is required for submersible deep-well pumps?

Maintenance for submersible deep-well pumps involves several key tasks to ensure optimal performance and longevity:

1. **Regular Inspection**: Periodically inspect the pump for any signs of wear, corrosion, or damage. Check the power cable for any abrasions or cuts.

2. **Performance Monitoring**: Monitor the pump's performance by checking the flow rate and pressure. Any significant drop could indicate a problem.

3. **Electrical Checks**: Ensure that the electrical connections are secure and that the motor is operating within the recommended voltage and current range. Test the insulation resistance of the motor windings.

4. **Vibration Analysis**: Conduct vibration analysis to detect any imbalance or misalignment in the pump, which could lead to premature failure.

5. **Bearing Inspection**: Check the bearings for wear and lubricate them if necessary, following the manufacturer's guidelines.

6. **Impeller and Casing Inspection**: Inspect the impeller and casing for any signs of wear or damage. Clean any debris that may have accumulated.

7. **Seal Inspection**: Check the mechanical seals for leaks and replace them if necessary to prevent water ingress into the motor.

8. **Water Quality Testing**: Test the water for sand, silt, or other particulates that could cause abrasion and wear on the pump components.

9. **Control System Check**: Ensure that the control system, including pressure switches and sensors, is functioning correctly.

10. **Backup System**: Maintain a backup system or spare parts inventory to minimize downtime in case of pump failure.

11. **Documentation**: Keep detailed records of all maintenance activities, inspections, and repairs for future reference and to track the pump's performance over time.

Regular maintenance helps prevent unexpected failures, extends the pump's lifespan, and ensures efficient operation.

How do you install a submersible deep-well pump?

1. **Preparation**: Ensure you have the necessary tools and equipment, including the submersible pump, safety rope, electrical cable, pipe, and fittings. Verify the well depth and diameter to select the appropriate pump.

2. **Safety First**: Turn off the power supply to the well. Wear protective gear, including gloves and safety glasses.

3. **Assemble the Pump**: Attach the pump to the drop pipe. Secure the electrical cable to the pipe using cable ties, ensuring it is not too tight to allow for expansion and contraction.

4. **Install the Safety Rope**: Attach a safety rope to the pump. This rope should be strong enough to support the pump's weight and long enough to reach the well's bottom.

5. **Connect the Electrical Cable**: Splice the electrical cable to the pump's motor leads using waterproof connectors. Ensure the connections are secure and insulated.

6. **Lower the Pump**: Carefully lower the pump into the well using the drop pipe. Ensure the safety rope and electrical cable are not tangled. Lower the pump slowly to avoid damaging the well casing.

7. **Secure the Pipe**: Once the pump is at the desired depth, secure the drop pipe at the wellhead. Use a well seal or pitless adapter to ensure a watertight connection.

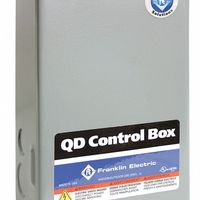

8. **Connect to the Power Supply**: Connect the electrical cable to the control box or pressure switch. Ensure all connections are secure and insulated.

9. **Test the Pump**: Turn on the power supply and test the pump. Check for proper operation, including water flow and pressure.

10. **Final Adjustments**: Make any necessary adjustments to the pressure switch settings. Ensure the system is operating efficiently and safely.

What are common problems with submersible deep-well pumps and how can they be fixed?

Common problems with submersible deep-well pumps include:

1. **Pump Failure**: Often due to electrical issues, overheating, or mechanical wear. Fix by checking electrical connections, ensuring proper voltage, and replacing worn components.

2. **Low Water Pressure**: Caused by clogged intake screens, worn impellers, or leaks in the system. Clean or replace intake screens, inspect and replace impellers, and check for leaks in pipes and fittings.

3. **Air Lock**: Occurs when air is trapped in the pump or piping. Bleed the system by opening a valve at the highest point to release trapped air.

4. **Short Cycling**: Frequent on/off cycling due to pressure switch issues or a waterlogged pressure tank. Adjust or replace the pressure switch and ensure the pressure tank is properly charged.

5. **No Water Delivery**: Can result from a broken drop pipe, a failed check valve, or a dry well. Inspect and repair the drop pipe, replace the check valve, and verify the water level in the well.

6. **Noise and Vibration**: Often due to misalignment, loose components, or cavitation. Realign the pump, tighten loose parts, and ensure the pump is submerged adequately to prevent cavitation.

7. **Corrosion and Scale Build-up**: Affects metal components and reduces efficiency. Use corrosion-resistant materials and regularly clean and descale the pump.

8. **Electrical Issues**: Include blown fuses, tripped breakers, or faulty wiring. Check and replace fuses, reset breakers, and inspect wiring for damage.

Regular maintenance, including inspection, cleaning, and timely replacement of worn parts, can prevent many of these issues. Always follow manufacturer guidelines and consult a professional for complex repairs.