- Home

- Fleet Vehicle Maintenance

- Garage Equipment

Garage Equipment

Garage equipment supports and facilitates maintenance and repairs on fleet vehicles. Vehicle lifting and support equipment raise vehicles or their parts off the garage floor for easy access to hard-to-reach areas. Creepers slide mechanics under vehicles to perform routine maintenance and repairs. Ga .....Read More

Frequently Asked Questions

What are the essential garage equipment supports for fleet vehicle maintenance?

How do vehicle lifting and support equipment work?

What are the benefits of using creepers for vehicle maintenance?

How do garage dollies assist in wheel and brake repairs?

What equipment is necessary for tire changing and balancing?

How do oil filter crushers contribute to waste reduction?

What are the best practices for using fuel cans and caddies safely?

How do vehicle extended reach platforms improve maintenance efficiency?

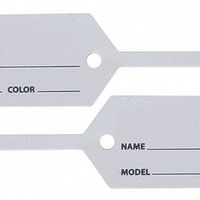

What is the importance of vehicle key tags in service departments?

How do vehicle protection covers prevent damage during storage or transport?