Double Diaphragm Pumps

Double diaphragm pumps are self-priming, drawing liquids from a source below the pump's inlet, and can run dry without the risk of damaging internal parts. They can handle liquids with suspended solids, varying viscosities, fuels, and oils. Diaphragm pumps are used for general transfer, dewatering, .....Read More

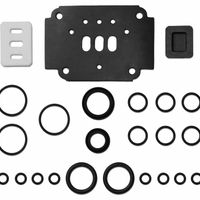

Air End Repair Kits for Double Diaphragm Pumps

Check Balls for Double Diaphragm Pumps

Diaphragms for Double Diaphragm Pumps

Fluid End Repair Kits for Double Diaphragm Pumps

Food Grade & Sanitary Air-Operated Double Diaphragm Pumps

Food Grade & Sanitary Electric-Operated Double Diaphragm Pumps

Industrial Air-Operated Double Diaphragm Pumps

Industrial Electric-Operated Double Diaphragm Pumps

Manifolds for Double Diaphragm Pumps

Mufflers for Double Diaphragm Pumps

Natural Gas-Operated Double Diaphragm Pumps

Pulsation Dampeners

Seats for Double Diaphragm Pumps

Frequently Asked Questions

What is a double diaphragm pump?

How does a double diaphragm pump work?

What are the advantages of using a double diaphragm pump?

What types of fluids can a double diaphragm pump handle?

How do you maintain a double diaphragm pump?

What industries commonly use double diaphragm pumps?

What is the difference between air-operated and natural gas-operated double diaphragm pumps?

Can double diaphragm pumps handle solids?

Are double diaphragm pumps suitable for hazardous environments?

How do you troubleshoot common issues with double diaphragm pumps?